A perfect fit for your application

We supply sophisticated sensor solutions - always precisely tailored to your specific application.

Long

life

We offer sensors in a wide range of designs with a long service life.

Easy fitting &

strong hold

Our sensors are quick and easy to install and guarantee a strong hold in all positions.

OPTICAL SENSORS

TO USE

DO YOU HAVE ANY QUESTIONS?

PLEASE CONTACT

WITH US.

We will be happy to answer any questions you may have about us and our services.

and our services, because your wishes are

wishes are important to us!

If you have any further questions about our products, we will be happy to be your first point of contact.

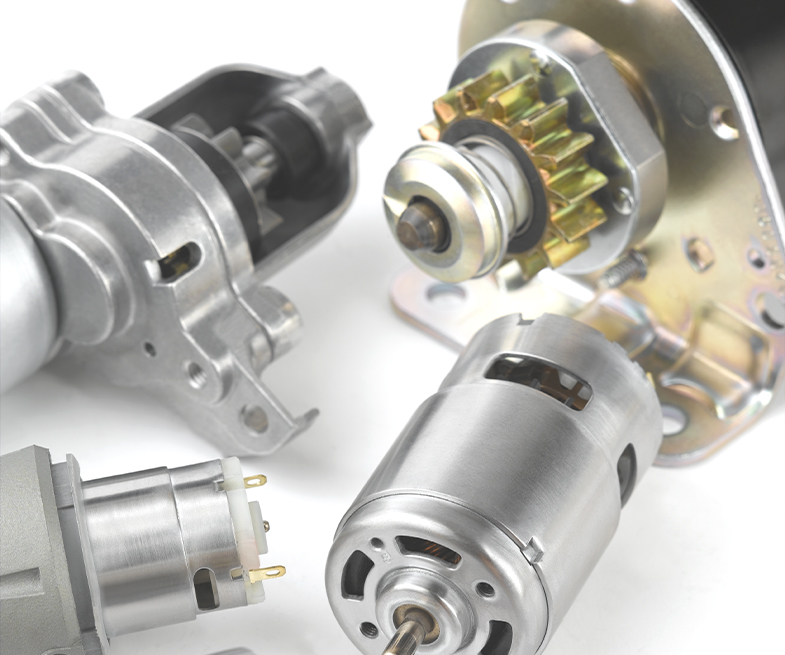

Optoelectronic sensors have the task of converting optical information into electrically evaluable signals. This is mainly limited to visible light, as well as infrared radiation and ultraviolet light. The basis of optical sensors is the conversion of signals by quantum mechanical effects of light.

Photocells, for example, use the external photoelectric effect. Optical sensors can also be based on the internal photoelectric effect, in which case they consist of semiconductors in which the action of light creates charge carriers that change the electrical properties of the material. The incident light therefore causes either a change in electrical conductivity (photoresistance) or a photovoltage (photodiode or photoelement). A variant of the internal photoelectric effect is the junction photoelectric effect, it is used in phototransistors and also photodiodes. Optical sensors in digital photo and video cameras (CMOS and CCD sensors) and in pattern recognition (e.g. barcode scanners) are often referred to as image sensors.

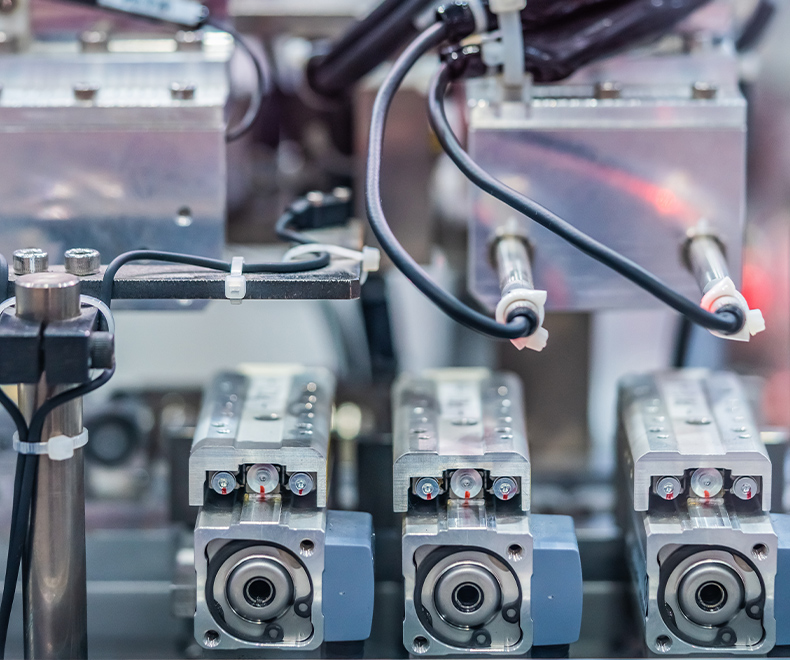

Optical sensors are used primarily in automation technology. There, in addition to simple recognition tasks, they are used for position measurement (e.g. light barrier), speed and angle measurement (e.g. incremental encoder) and distance measurement.

Optical sensors are at the heart of advanced manufacturing automation. Their reliability determines the function of the entire system. The properties have a decisive influence on your costs, economic efficiency and quality. Pepperl-Fuchs offers one of the largest ranges of modern optoelectronic sensors with the VISOLUX brand.

- Standard sensors

- Safety Sensors

- Sensors for doors, gates and elevators

- Special sensors

- Optoelectronic accessories

Series: OGU, OGUH, ODG

Features:

- Fork widths from 2 mm to 220 mm

- Special designs according to customer requirements

- Metal connector

- Ring-LED

- Sensitivity adjustable

- Electronics integrated

- Switching frequency up to 10 kHz

- Light/dark switching

- Protection class IP 67

- 2-beam forked photoelectric sensor with differential evaluation;

resolution from 0.07 mmAnwendungsbereiche:

Use in conveyor technology, assembly automation, feeding automation, mechanical engineering (e.g. packaging machines, woodworking machines, special machine construction, etc.) Presence control, positioning tasks, etc.

Series: LGU / LGUP

Features:

- Collimated red light laser, clocked

- Detection of smallest parts

- High resolution

- High switching frequency

- Reproducibility 10 μm

- Laterally stackable

- Light/dark switching

- Metal housing

- Laser protection class 2

- Protection class IP 67

- Ring LED

- LGUP power version

- Red light laser

Areas of application:

High-precision positioning in packaging technology Saw tooth positioning Detection of a groove Detection of the unbalance of a shaft.

Series: OGL / OGLP / LG

Features:

- Application-related further development of the forked photoelectric sensors

- Optical axis can be approached in x, y and z direction

- Universal mounting on three sides

- Sensitivity adjustable

- Light/dark switching

- Metal housing

- Steel housing galvanized (not all types, see data sheet)

Areas of application:

Parts detection in feeding rail, stack height control, parts detection, in roller conveyor with quality control on micro components mounted air purge di-soric_reflective light barriers.